SIEG X3 Small Mill /

Grizzly G0463

WARNING! All the

material on this page comes from a variety of sources.There

are at least three different owner's manuals, with a real

early one, then a 2005 version, then a 2009 version.This

material is presented "As-Is", if you choose to use it, it's

YOUR responsibility.TTC Model 811-301 Display [no datasheet or guide]

Chinese Scales on Schumatech [correct for the period, might not apply today]

Reliability and the Chinese Scales "Experience" edited by Bill Havins

Grizzly G0463 User's Manual After November 2005

X3 Speed Controller PCB Schematic by Les [Jones?]

X3 Speed Controller PCB Operation

X3 Small Mill Dismantling and Reassembly Guide by Arc Euro Trade Ltd

THE classic guide. Read, Think, and Do...

Grizzly H8178 - Table Power Feed for Mill/Drills [installed it, but removed it...]

Grizzly T10896 - Power Feed for G0463 and G0619 Mills [new to me...]

Grizzly G1049 6" Rotary Table [27 lbs, handwheel extends below top of bed! ]

Kalamazoo Industries A1 5C Collet Indexing Fixture

Takes 4″ chuck, 3 jaw 1043. 5C shank Back plate [used on grinding machines].

A1 Parts List

Buck Adjust-Tru 4" Chuck 1432 - 3 jaw, 1462 - 6 jaw

Mount and Adjust Adjust-Tru Chuck

Buck Tool Co.Catalogs on VintageMachinery.org

Kalamazoo Chuck Manufacturing

Founded by a former owner of Buck Chuck Company in 1998

Manual Chucks Catalog, pg 4, Micro Set Chucks w/Semi-Steel Body, B4343

Does not look to be Adjust-Tru

Gerling Laboratories [Mill DC Drive Repair, closed @ 2010 :( ]

Little Machine Shop [LMS]

G0463 Parts [closeout 20250512 !]

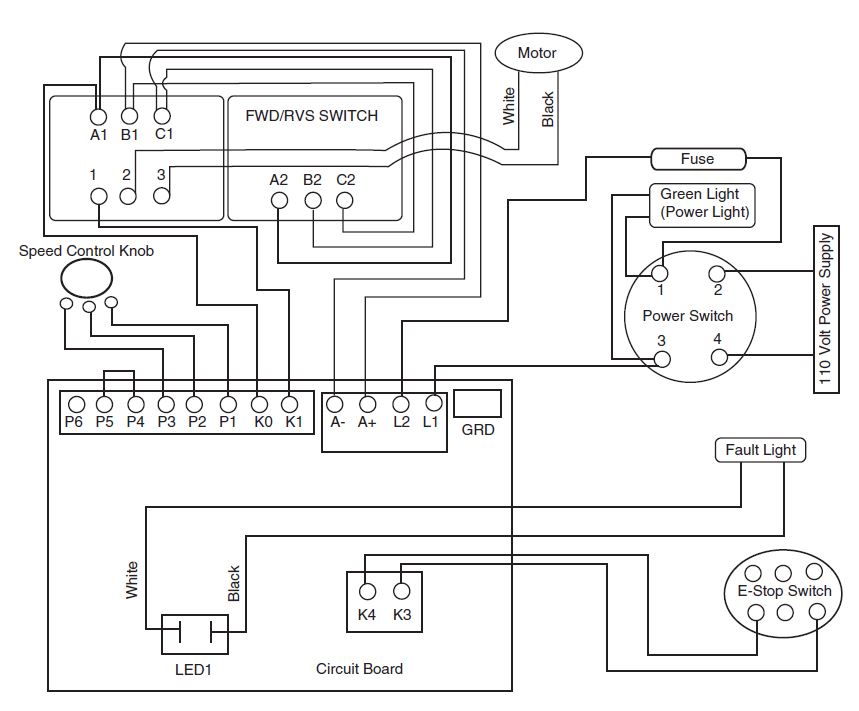

4511 Wiring Diagram SIEG X3 and Grizzly G0463. XMT-1160 control board.

4513 Wiring Diagram power feed for X3. XMT-1115J control board.

Grizzly Parts for G0463 - 6" x 22" 3/4 HP Mill/Drill

Fixture and Workpiece Weight - I bought a 6" rotary table. Bulky. I asked Grizzly for a weight limit on fixtures / work pieces, and I dimly remember @ 100 pounds. Maybe with that much weight at the end of a fully traversed table the mill wants to "tip". Securely fastening the mill's base to a bench or stand -MIGHT- change this. Might also be that much weight off-center would put more force on the lead screws and gibbs? YMMV.

DC Motor controllers ["Drives"] that have been mentioned being used:

XMT-1160 [SIEG part]

P0463220 [Grizzly]

Minarik MM23001C

KBIC-125

Bought a G0463 Small Mill in the mid-2000s. Took it apart, cleaned and lubed it, re-assembled it [no parts left over! ]. Eventually put some cheap-o Red Chinese scales on it, hooked them up to a TTC Model 811-301 Display, cobbled together a Z-axis scale using a quill clamp, an aluminum base, and milled a pocket for a magnet.

XMT-1160 or Grizzly P0463220 Wiring Diagram

FWD/REV switch is also called a Forward/Off/Rev [F/O/R] switch.

Motor

ZYT-600 Brushed Permanent Magnet DC motor. 600w [0.8HP], 110v, 6.5A.

Looks to be a 90ZYT model, 90mm dia, motor length [sans square mounting plate] is 199mm. Haven't been able to pin the exact model down.

TTC Model 811-301 Display [no datasheet or guide]

Seems to be discontinued [surprise! ]. I don't even know the manufacturer. Who is "TTC" ?

This uses 3x RJ11 jacks, and the cables are securely held into the Display Unit. However, the scales use a plug that requires perfect seating, and moving the table flexes that plug.

Kalamazoo Industries A1 5C Collet Indexing Fixture (Page at Kalamazoo)

5C adapter plate image from midmichsupply

This is the 5C mounting plate for 4" chucks used with the A1. This style is used with indexers, rotary tables and grinders.