NOTE:

NOTE: For the 300

H & H and 375 H & H MAGNUM

On these long magnum cases it is necessary to allow 1/2" between

the top of the shell holder and the bottom of the die body. All

other instructions are correct for these two cartridges and should

be followed.

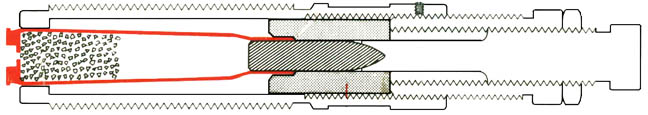

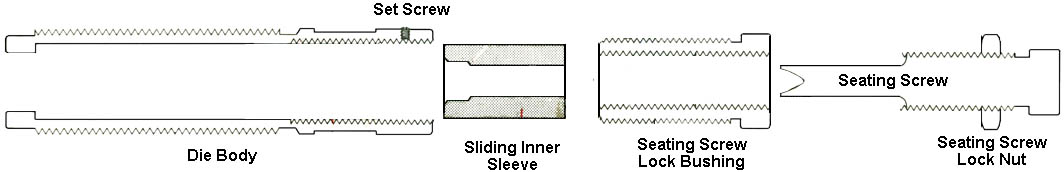

This shows a cutaway view of a P-A Bullet Seating Die. This die features a sliding inner sleeve which aligns the bullet and case neck. The sliding sleeve also contains a built-in crimping shoulder which may, or may not, be used depending upon the reloaders' preference. The cartridge case in the illustration is shown in the non-crimp position.

The die is adjusted as follows: loosen the set screw in the large

hex lock nut located on the outside of the die. Screw this lock

nut toward the knurled end of the die. This will give you room to

thread the die into the press. Lower the press handle until the

shell holder is at its highest point. Screw the die into the press

until the bottom edge of the die makes firm contact with the shell

holder. Note: 300 H

& H and 375 H & H do not touch shell holder. See note at

top of page. When your die bottoms firmly on the shell holder,

tighten the lock nut and set screw.

The seating screw bushing, located in the top of the die body,

regulates the crimp. Turn this bushing out (counter clockwise)

until it is almost free of the die body. Place an empty sized

cartridge case in the shell holder and pull down on the press

handle until the shell holder is at its highest point. Turn in

(clockwise) on the bushing until you "feel" it bottom lightly on

the sliding inner sleeve. When you feel it contact the inner

sleeve, back off 1/4 turn and tighten the set screw located in the

side of the die body. Your cartridge is now in the non-crimp

position shown in the illustration.

Your bullet must now be seated to the proper depth. Turn out the

seating screw about 1/2". Place a cartridge in the shell holder

and a bullet in the mouth of the case. Pull down on your press

handle until your shell holder is again at its highest point and

turn down the seating screw until it comes into contact with the

bullet.

Alternately raise the handle and turn down the bullet seating

screw a little at a time until the bullet is seated to the desired

depth. Once your bullet is seated to the depth desired tighten the

seating screw lock nut. Your die is now adjusted to seat bullets

without crimping.

CRIMPING

If you wish to crimp on jacketed bullets which have crimping

grooves, continue as follows: make certain your bullet is seated

exactly to the crimping groove. Loosen the set screw which is

holding the seating screw bushing and turn in (clock-wise) 3/4 of

a turn on the bushing. Re-tighten your set screw and your die will

be adjusted to crimp the bullet in place.

The unique design of your P-A Bullet Seating

Die affords a high degree of interchangeability between different

calibers. In some instances, the same die is used for several

calibers. Where this occurs, a list of these calibers are marked

on the die body. In other instances, changing the seating screw,

sleeve, or die body will convert your die to another caliber.

Die Bodies

Die bodies are 305, 355, 383, 428, 452, 467, 478, 506, 520 (467

peculiar to 30/40 Krag)

They were bored from the top to a standard

configuration, with the only difference being in the lip around

the mouth of the die. This "lip" provided better centering

of the case head in the die. [Ed.]

There are short PA dies, like the 256 Win Mag. If I get more

information on the die body lengths, I'll post it.

Seating Screws

I have a 450 and a 450A in hand. Oddly, there

does not appear to be any difference in tip radius. It may be

there are different seating screws for jacketed and cast bullets,

but I can't prove it... [Ed.]

The possibility exists that a standard Seating Screw will fit into

the Sliding Sleeve. But the standard die Seating Screw will be

shorter than the PA Seating Screw, so the standard Seating Screw

will have to screw farther into the Seating Screw Bushing in order

to work... My SWAG is analogous to a 7x57 working with the

standard (short) Seating Screw, but the 7mm BR would not, since

the case body is shorter... [Ed.

just a match made at random, I have no way to verify this!]

There appears to be three Seating screws.

450A 22 cal - 28 cal .221 dia x 1.000 long

467A 30 Cal - 32 cal .304 dia x 1.000 long

999A 33 cal - 37 cal .332 dia x .995 longSleeve

Dimensions

Sleeves are all .619 dia by 1.00x long and were available in 22 (.227 ID), 24, 25 (.260 ID), 26 (.266 ID), 27 (.279 ID), 28, 30 (.311 ID), 31, 32, 32A (?), 33 (.340 ID), 35 and 37 calibers

If you can enlighten me with further information, I'd love to get it Contact me. A list of the PA number to supported cartridges, for one.

Needed PA die numbers:

PA12, PA14, PA25, PA27, PA28, PA30

| Die |

Cartridge |

Body |

Sleeve |

Seat Screw |

|

PA1 |

22 Jet, 221, 222, 222 Mag, 223 Rem |

383 |

22 |

450A |

|

PA2 |

219 Zipper, 225 Win |

428 |

22 |

450A |

|

PA3 |

|

|

|

|

|

PA4 |

|

|

|

|

|

PA5 |

.220 Swift, .220 Weatherby |

452 |

22 |

450A |

|

PA6 |

22/250 |

478 |

22 |

450A |

|

PA7 |

.243, 244 (6mm Rem) |

478 |

24 |

450A |

|

PA8 |

250 Sav (250/3000), 257 Rob, 25-06 |

478 |

25 |

450A |

|

PA9 |

25 Rem, 25/35 |

428 |

25 |

450A |

|

PA10 |

256 Win Mag |

383 |

25 |

450A |

|

PA11 |

25-20 |

355 |

25 |

450A |

|

PA12 |

|

|

|

|

|

PA13 |

6.5 Jap, 6.5 Ital, 6.5 M.S. |

452 |

26 |

450A |

|

PA14 |

|

|

|

|

|

PA15 |

.264 Win Mag, 6.5 Rem Mag |

520 |

26 |

450A |

|

PA16 |

|

|

|

|

|

PA17 |

25 Rem |

428 |

25 |

450A |

|

PA18 |

7x57mm, 280 Rem |

478 |

28 |

450A |

|

PA19 |

284 Win |

506 |

28 |

450A |

|

PA20 |

7mm Rem Mag, 7mm Wea, 7x61 S&H |

520 |

28 |

450A |

|

PA21 |

30/30, 30 Rem |

428 |

30 |

467A |

|

PA22 |

30/06, 300 Win, 300 Savage |

478 |

30 |

467A |

|

PA23 |

30/40 Krag |

467 |

30 |

467A |

|

PA24 |

308 N. Mag, 300 W. Mag, 300 Wea, 300

H&H |

520 |

30 |

467A |

|

PA25 |

|

|

|

|

|

PA26 |

|

|

|

|

|

PA27 |

|

|

|

|

|

PA28 |

|

|

|

|

|

PA29 |

32/20 |

355 |

31 |

467A |

|

PA30 |

|

|

|

|

|

PA31 |

8x57mm, 8mm M.S |

478 |

32A |

467A

|

|

PA32 |

|

|

|

|

|

PA33 |

35 Rem, 35 Win |

467 |

35 |

999A |

|

PA34 |

350 Rem Mag, 350 Norma Mag |

520 |

35 |

999A |

15 July 2018:

Thanks to Scott Haenel for the identities of

PA 4, 16, and 32.

Thanks to Neil for confirming PA26 as the .303

British.

22 Sep 2018

Thanks to Scott Haenel for the Sleeve

IDs for .270 and .338, also the Seating screw

dimensions for 999A.

25 July 2019

Brian Hill confirms the PA16 is the .270 Win, Sleeve 27,

seating screw 450A

The

chart below lists the various calibers for which P-A Dies are

available. It shows the part numbers for the various body sizes,

sleeves and seating screws which make up each die. The same die

may be used for any caliber which has matching part numbers. Where

numbers vary, new parts or required for the conversion. Specify

the part, and part number, when ordering.

Original names for Conversion Parts:

SEATING SCREW w/CHECK NUT (eg. Seating Screw Lock Nut)

INNER SLEEVE

DIE BODY w/CHECK NUT

|

Caliber |

Body |

Sleeve |

Seating

Screw |

|

22 Jet |

383 |

22 |

450A |

|

.221

Fireball |

383 |

22 |

450A |

|

.222 Rem |

383 |

22 |

450A |

|

.222 Rem Mag |

383 |

22 |

450A |

|

.223 Rem |

383 |

22 |

450A |

|

.219 Zipper |

428 |

22 |

450A |

|

.225 Win |

428 |

22 |

450A |

|

.224 Wea. |

428 |

22 |

450A |

|

.218

Bee |

355 |

22 |

450A |

|

22

Hornet |

305 |

22 |

450A |

|

22K

Hornet |

305 |

22 |

450A |

|

.220

Swift |

452 |

22 |

450A |

|

.220

Wea Rocket |

452 |

22 |

450A |

|

22/250 |

478 |

22 |

450A |

|

.243 Win |

478 |

24 |

450A |

|

.244 Rem |

478 |

24 |

450A |

|

6MM Rem |

478 |

24 |

450A |

|

250/3000 |

478 |

25 |

450A |

|

.257 Roberts |

478 |

25 |

450A |

|

25/06 |

478 |

25 |

450A |

|

25 Rem |

428 |

25 |

450A |

|

25/35 |

428 |

25 |

450A |

|

25/20 |

355 |

25 |

450A |

|

.256

Win |

383 |

25 |

450A |

|

.257

Wea. |

520 |

25 |

450A |

|

6.5

Jap. |

452 |

26 |

450A |

|

6.5

Ital. |

452 |

26 |

450A |

|

6.5

M.S. |

452 |

26 |

450A |

|

6.5 x

55 |

506 |

26 |

450A |

|

.264

Win. |

520 |

26 |

450A |

|

.270

Win |

478 |

27 |

450A |

|

.270

Wea. |

520 |

27 |

450A |

|

7 x 57

MM |

478 |

28 |

450A |

|

.280

Rem |

478 |

28 |

450A |

|

.284

Win. |

506 |

28 |

450A |

|

7 MM

Rem Mag. |

520 |

28 |

450A |

|

7 MM

Wea. |

520 |

28 |

450A |

|

7 x 61

S&H |

520 |

28 |

450A |

|

30/30

Win. |

428 |

30 |

467A |

|

30 Rem |

428 |

30 |

467A |

|

.300

Sav. |

478 |

30 |

467A |

|

.308

Win |

478 |

30 |

467A |

|

30/06 |

478 |

30 |

467A |

|

30/40

Krag |

457 |

30 |

467A |

|

.308

Norma Mag. |

520 |

30 |

467A |

|

.300

Win Mag. |

520 |

30 |

467A |

|

.300

Wea. |

520 |

30 |

467A |

|

.300

H&H |

520 |

30 |

467A |

|

7.65

Arg. |

478 |

31 |

467A |

|

7.7

Jap. |

478 |

31 |

467A |

|

.303

British |

467 |

31 |

467A |

|

.303

Sav. |

452 |

31 |

467A |

|

7.62

Russ. |

506 |

31 |

467A |

|

32/20 |

355 |

31 |

467A |

|

32 Rem. |

428 |

32 |

467A |

|

32 Win

Spl |

428 |

32 |

467A |

|

32/40 |

428 |

32 |

467A |

|

8 x 57

MM |

478 |

32A |

467A |

|

8 MM

M.S. |

478 |

32A |

467A |

|

.338

Win Mag. |

520 |

33 |

999A |

|

35 Rem |

467 |

35 |

999A |

|

35 Win. |

467 |

35 |

999A |

|

.350

Rem Mag. |

520 |

35 |

999A |

|

.358

Norma Mag. |

520 |

35 |

999A |

|

.358

Win |

478 |

35 |

999A |

|

.375

H&H |

520 |

37 |

999A |

|

.375

Wea. |

520 |

37 |

999A |