Inexpensive Ammunition For The Krag

Army-Navy Register and Defense Times, vol 36, No 1291, Sep 10, 1904 – pages 9-11

The most expensive parts of the modern cartridge are its shell and its bullet. The primer costs practically the same as ever, and while the smokeless powder costs considerably more per pound than the old black powder, less of it is used tor a charge and in any event the expense of the powder charge is a small matter as compared with that of the shell and jacketed bullet.

But there are several ways in which any military organization can multiply many times the number of practice shots than can be obtained from a given allowance for ammunition and a discussion of these is the object of the present paper.

There are many opportunities for practice where the great energy of the full service charge is not required and is indeed undesirable. The first of these is the indoor armory range practice, which is generally conducted at ranges of less than 100 yards. Here it is desirable to have a very light and inexpensive charge, and there are several ways of accomplishing this, of which we may consider the following:

(1) The steel bushing and other forms of sub-cartridge holders. '

(2) The gallery rifle.

(3) Reduced loads in the service shell.

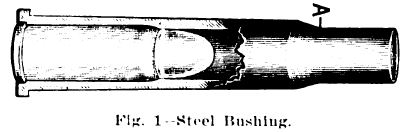

The Steel bushing. (Fig. 1) is merely a plug of steel having the outside dimensions of the service shell, but bored and chambered so that a pistol cartridge may be loaded into it, and the bushing containing the pistol cartridge loaded into the chamber of the rifle. Since recent improvements in the smokeless powder used for pistol cartridges have been made. fairly good results can be obtained from the bushing and it affords what is an undoubted advantage to some, in that ready made pistol cartridges can be used by its means. The best results I have been able to obtain with the bushing have been with the 32. cal. Colt New Police cartridge (Fig. 2) which is loaded with 2 grs. of “Bullseye” smokeless powder.

Fired from the machine rest, this gives groups averaging 3 ½ to 4 ½ inches in diameter, at 70 yards. The lowest quotation I have been able to get on these is $9 per thousand, which is about three times as much as the cost of some of the lighter loads in the service shell: but where the labor involved in the reloading operation is hard to obtain, even this increase in cost may be preferable.

The bushing has given trouble in several ways. First, no matter how good the material used, it has a tendency to split at the neck, owing to the loose chambers on so many of the Krags. This can be overcome by cutting off the neck at A, Fig. 1., but only at some sacrifice of accuracy. Another fault is that the bullets have acquired so much velocity by the time they strike the rifling that there is a strong tendency to lead the barrel. Escape of gas at the breech, too, sometimes occurs; this is not only unpleasant to the shooter, but is also deleterious to the bolt mechanism of the rifle unless it be taken apart frequently and cleaned.

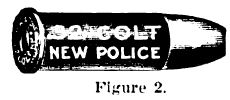

Several years ago, when I was conducting a series of experiments with the bushing, these faults impressed me so strongly that I sought for a means of overcoming them. I succeeded in a great measure by the device shown in Fig. 3., and for those to whom the above enumerated advantages of the bushing appeal more than its disadvantages, I think would prove more satisfactory than the plain bushing.

It consists of an outer shell (a) of spring tempered steel, the size and shape of the service shell back of the neck. Inside of this is a steel plug (b) traversed by a phosphor-bronze firing pin. The front part of the device is recessed, essentially as shown, for the reception of a pistol cartridge like the 32 Colt Police. The outer shell has four or more longitudinal cuts extending from its muzzle to about the point (e), so as to divide it into several prongs which can be sprung apart to permit the pistol cartridge to be easily inserted or extracted from the front end. When loaded into the gun, the chamber holds these prongs together in such a manner, that if nicely made, there is scarcely any space between them. By this device, when the bullet leaves the shell, it is already at the beginning of the rifling, and the natural result is much better shooting than with the plain bushing. The dimensions of the .32 Colt Police cartridge well adapt it to this device.

Efforts have been made at various times to cover these bushings, sub-cartridge holders, breech adapters or whatever one pleases to call them, by patents. It is doubtful if any of the patents would hold good, however, as the ideas in various combinations are old and have been used in this country and in England for years. It might be of advantage to the shooting fraternity if some one could be induced to manufacture the holder shown in Fig. 3 and place it on the market at a low price. I had several made by Mr. Geo. W. Best, 101 Fisher Building. Chicago. Ill., and I presume if there was enough demand for them he might be willing to undertake their manufacture.

What I believe would be the best way, however, of obtaining cheap gallery practice where the reloading process must be at abolished, is to have a few of the service rifles set aside for gallery use and so altered as to fit them expressly for this purpose. Thus, the .30 calibre barrel of the Krag could he replaced by one properly rifled and chambered to handle the .22 cal. “long rifle" cartridge (Fig. 4), which can be bought for about $2.90 per thousand, and which is extremely accurate, at ranges up to 100 yards.

To use this cartridge, the firing pin would have to be altered so as to strike in the right place. The alterations would probably cost $10 to $20 each, depending upon how many rifles were altered at the same time; but as in no case could more rifles be used at once than the number of ranges provided in the armory, the number would not have to be great, seldom over 12.

A barrel for any of the centre fire pistol or rifle cartridges would not require alteration of the bolt, and the rifle so altered would be less expensive and would shoot better than any bushing or similar device; but the ammunition would cost about three times as much as the 22 cal., so that it would be questionable economy.

This brings us to the question of suitable reduced loads in the service shell. And it is an undeniable fact that many very satisfactory loads of this kind have been produced during the past few years, through the efforts of riflemen with an experimental turn of mind—our so-called "rifle cranks."

As a rule, the labor involved in the reloading processes is easily available in all military organizations. In most of the militia regiments, this work is left to the armorer and his corps of assistants. But it would be far better if the men themselves could be induced to take an interest in preparing their own ammunition, under the supervision of proficient instructors until they became expert at the work. It is not a dangerous operation, as many have supposed, if ordinary common sense precautions are adopted; it is not hard work, but on the contrary soon becomes quite interesting: and nothing puts a rifleman so thoroughly in touch with the art of shooting as preparing his own ammunition. It teaches him to reason from cause to effect, and from effect to cause.

The great saving in expense is effected by the elimination of the cost of the brass shell and the jacketed bullet. Many of the smokeless cartridges issued by private makers bear an inscription upon the box stating that "these shells cannot be reloaded." Of course it is to their interest not to have them reloaded, for they have new ones to sell; and indeed most of the shells of private manufacture are made so thin that they are really not well suited for reloading.

Added to this is the fact that they are generally supplied with primers containing fulminate of mercury, which under the heat and pressure developed by the service load has a very bad effect upon the brass, causing it to become brittle, and weak in the course of a few days after firing. But the shells supplied by the Frankford Arsenal with "H 48" primers can be reloaded with either the full or the reduced load; moreover, they will stand reloading many times before they give out. Whatever fault one may find with some of the products of the government arsenals, we must heartily applaud the producers of the Frankford .30 calibre shell and the H 48 primer, for they are so far unequally; and the statement on the box of private make cartridges, "These shells cannot be reloaded," should be regarded as a confession of inferiority.

Fortunately, large quantities of Frankford shells that have been fired with the H 48 primer can generally be picked up at the range after matches or practice calling for service cartridges. Therefore, if proper care be taken of these, the cost of the most expensive part of the cartridge—its brass— is eliminated.

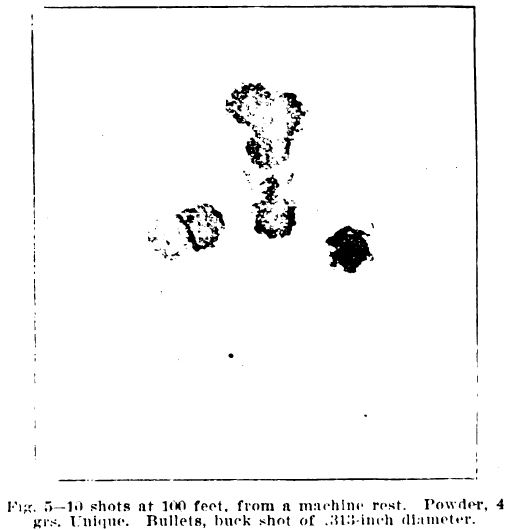

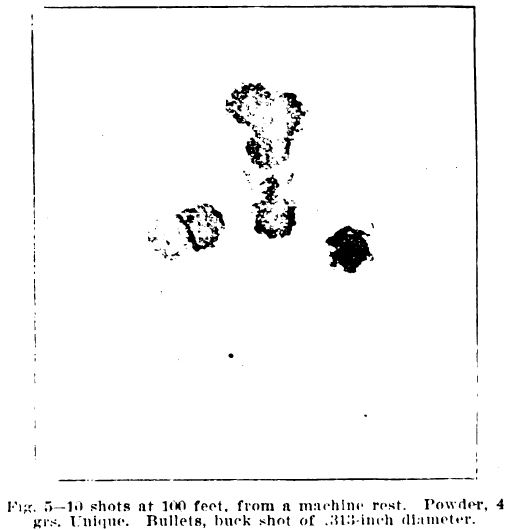

For the reduced loads now under consideration, metal jacketed bullets are not necessary nor even desirable. The necessary hardness of the bullet to stand the quick twist of the Krag can be supplied by alloying suitable proportions of tin and antimony with the lead in ordinary home made cast bullets. If for very short range work, calling for only the lightest charges of powder, even the ordinary buck shot can be used (Fig. 5.) But it should be much larger than the round bullets supplied by the government arsenals, which were seated in the neck of the shell. The small size of the government round bullet is one of the chief causes of the dissatisfaction it gave.

In any case it is better to mould even the round bullets, for then they can be hardened; but as it is just as easy to mould bullets of a better shape, I do not recommend round bullets except where one must avoid the moulding process.

The expense of the alloy for cast bullets is almost nothing for by the use of a suitable bullet catcher the material can be used over and over again; the loss is so light that it can be almost disregarded.

The steps in reloading the service shell are as follows:

(1) Decapping. (2) Washing the shells, and drying them. (3) Re-sizing. (4) Re-priming. (5) Expanding and removing the crimp. (6) Re-charging with powder. (7) Seating the bullet.

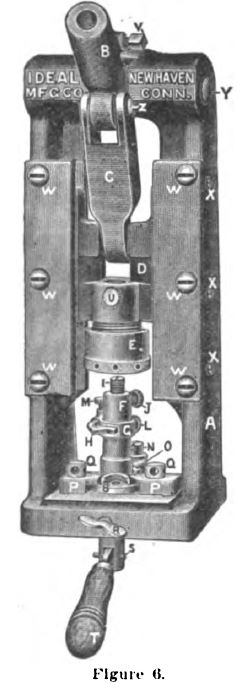

All of these operations except the washing and

re-charging with powder can be done on the Ideal loading press

(Fig. 6.) But as it is better to do some of them by other means,

we will discuss each one separately.

(1) Decapping. While the Ideal press does this very easily, removing the old crimp at the same time, it can be done very readily by means of a brass or iron rod about 3 ½ inches long and .305-inch diameter, set firmly into a chisel handle, and carrying a spring-tempered steel pin at the end. (Fig. 7). The advantage of using this is that it leaves the press free, so that another man can use it to carry out one of the other operations at the same time.

(2) Washing the shells will be greatly facilitated if they are arranged in a wire basket, or in a rack made of parallel wires like a gridiron, so that the mouths will all be down. It is then merely a question of dipping them a few times in the cleaning solutions and finally in water. Hot soap suds, and a hot solution of washing soda have been successfully used. Whatever solution is used, the final washing in boiling water should be thorough, so as not to leave any foreign material in the shells, and this is where the advantage of having them all inverted in a wire basket or rack is most noticeable, for then you are sure that all the washing solution has drained out. The drying, too, is greatly facilitated by this means. Never at tempt to dry the shells by putting them into a hot oven, as this will alter the hardness of the brass. In summer they will dry quickly enough if exposed to the sun‘s heat; otherwise the drying process may be facilitated if necessary by gentle heat, but never allowing them to get hotter than boiling water.

Shell washing is an operation that is generally regarded as indispensable, and undoubtedly it is best to do it. But in spite of this one can often obtain very good results from ammunition loaded into dirty shells, providing it is not kept loaded too long before using. This .s especially the case when the dense Laflin & Rand powders are used. I dislike to advise such a proceeding for it is certainly misusing any powder to load it into dirty shells. But as unusual stability is one of the strongest points urged by the makers of this brand of powder, we might well take all possible advantage of it if we can thereby save the disagreeable shell washing process.

“Foot Note."—Other chemical solutions for cleaning shells thoroughly will be found in the writer's book, “Modern Rifle Shooting” published by the Laflin & Rand Powder Co., P.O. Drawer 1001, Wilmington, Del.

(3) Re-sizing. Resizing the shells will have to be done if there is much difference in the size of the chambers of the various guns in which the cartridges are to be used. It is best to resize all of a newly acquired lot of old shells once at the start, at any rate, then try them in various guns of the command after the first firing, to see whether subsequent re-sizing will be necessary. The last part of the closing motion on the action of the Krag is so powerful that even though the shells are slightly expanded from firing in a larger chamber, they can be forced in. If the repeated re-sizing can be avoided, not only will that much work be saved but the shells will last longer.

The re-sizing operation, as conducted on the Ideal loading press, is where this tools excels everything that has heretofore been used. It is an operation that requires considerable power, and yet on this machine it can be done with very little effort.

The operation may also be conducted, though much more laboriously, upon a government re-sizer, or even in a plain steel die that can be bought for one or two dollars. In the plain die, the shells have to be driven in with a mallet, and then driven out again.

(4) Re-priming. The best primers to use, if permission can be obtained to buy them from the government, are the H 48 Frankford primers. The U. M. C. Co. also make a non-mercuric primer which they list as the 9 ½ . If any use is to be made of the shells after firing with the service charge, it is important that the service charge be fired with one or the other of these. For the reduced loads, in addition to the above primers the 7 ½ and 8 ½ U. M. C., and the 2 ½ W Winchester primer may be used, for the mercury does not attack the shell so badly under the lower pressures.

The re-capping can be done in the Ideal press at the same time as the sizing operation, or it may be done separately by means of a cheap hand capping tool. The government also supplies a very effective tool for this purpose. In any case, be sure that the primer is seated all the way, or the cartridge may go off prematurely on loading the rifle. Once in a while a primer is exploded in seating it; therefore do not have any loose powder lying around during this operation, to catch fire if one should explode.

(5) The next operation is to open the mouth of the shell, if it is not already in a condition to receive the bullet without taking a shaving off its side or otherwise damaging it. A useful addition to the Ideal press which the manufacturers now supply consists of a steel plug of the required diameter, which when forced into the month of the shell leaves it exactly right. If the diameter of the plug used is l or 2 thousandths of an inch larger than the bullet, the bullets can be seated in the shells with the fingers alone. This is the easiest way to prepare ammunition when intended solely for use on the armory range. But when it is to be used outdoors, or carried in the belt, or subjected to much handling, it is better not to expand the shells too much and to force the bullets home by means of the seating chamber.

(6) Recharging with powder. The kind and amount of powder required will vary with the bullet used. The charge can be measured either by means of a scoop, or by means of the Govt. or Ideal powder measure. The best scoop is one designed by Mr. Ed. Taylor, of the Laflin & Rand Powder Co., which is adjustable and can be set for any charge. It can be obtained from that company, 99 Cedar St., N. Y. City, for 25 cents. The Ideal powder measure No. 5 is also a very convenient little machine for measuring powder. Both the scoop and the measure are accompanied by tables showing how to set them for a given weight of powder; but in my opinion it is always better, before proceeding to load cartridges in any extensive way, to throw a few powder charges upon the pan of an apothecary scales to verify their weight. All powder charges mentioned in this paper are in grains actual weight.

(7) Seating the bullets. This is an operation which is done to perfection in the Ideal loading press. If the jacketed bullet and service charge of powder are to be reloaded. it is better to use shells that have been resized, for the expanded shells will not properly hold the jacketed bullet. But as all of the cast bullets are necessarily made larger than the jacketed bullets, they seldom require the shells to be resized for this reason.

For armory use, many riflemen prefer to have the neck of the shell so expanded, either from previous firings or from the use of the steel expander, that the bullet can be inserted with the fingers and without the aid of a loading machine. When they are as loose as this, it is necessary with most bullets to provide against their dropping into the body of the shell.

This can be prevented by making a few indentations in the neck of the shell by means of the shell indenter (Fig. 8), which is another one of Mr. Taylor's inventions. It is better to do with out the indentations if possible, as they weaken the shells somewhat. The round ball used, as I have described, and bullets Nos. 308256, 308257 and 308259 (Fig 9) do not require any indentations; their front band is much larger than the inside diameter of the neck.

IMAGE_09 - Article images are poor, better ones

in Ideal catalogs... More futzing, but it should be worth it...

This brings us to a consideration of the bullets themselves. Fig. 9 illustrates all the cast bullets that have been, to my knowledge, used successfully in the Krag. For miniature loads adapted only to armory ranges there are so many bullets which give fine results that one is at a loss which to recommend for the purpose. Taking everything into consideration, for very short ranges, I am inclined to favor Captain Young’s bullet (No. 308257) with 5 or 6 grains of Infallible or Unique powder.

My own investigations on bullets for the Krag have been directed chiefly toward getting as heavy a load as possible, while still using the inexpensive cast bullet. Contrary to the prevailing opinion, when the weight of the bullet and the powder charge are increased so as to get longer range, the difficulties that arise are not due so much to failure of the bullet to follow the quick twist as to the intense heat developed by the smokeless powders.

Alloys of lead, tin and antimony can easily be made hard enough to answer for this purpose but unfortunately their melting point is so low that there is great difficulty from fusing of the base of the bullet. This is particularly noticeable if there is any leak of gas past the bullet, when the streaks of fusion up the sides, showing where the gas has melted a passage past the bullet, are very much in evidence. Bullets having much fusion assume a wobbly, corkscrew flight, and cannot be made to shoot accurately.

I have been working on this problem for a long time, and have obtained the most powerful successful load with bullets Nos. 308256 and 308259. They can be loaded with a sufficiently heavy powder charge to give 1,350 to 1,400 feet per second velocity; this velocity being obtained with 15 to 16 grains of New Schultz or Marksman powder. Further than this it has so far been impossible to go, without using a gas-check or adopting other expedients which interfere with the simplicity of the loading process. But these loads will be found to give good results up to 500 or 600 yards; and while they are not equal to the service load at these ranges, and are of course more sensitive to the wind, I believe they will be found good enough for class practice where low cost is a vital consideration. We are still experimenting in the hope of getting 1,500 F. S., which it is believed will make a load almost equal to the service load in accuracy at the mid ranges.

But for armory use, on ranges of 70 to 100 yards, these two bullets give results that are as near perfection as can be desired. We are using them, with powder enough to give 1,280 F. S. velocity, on the 70 yard ranges of the 9th Regt., N. G. N. Y. The ammunition so prepared appears to be much more reliable than the lighter charges, and we have not found it too powerful for armory use. Thirteen grains of New Schultz or Marksman powder are sufficient to give this velocity, and the bullets are cast from No. 2.alloy. If more than 13 grains of powder are to be used, the bullets should be cast of N0. 3 alloy.

These bullets also have the enlarged front band, which while it incidentally prevents the bullet from receding into the shell, was put there more for the purpose of acting as an absolute gas check even before firing, by being forced into the riding in the act of closing the bolt. Its dimensions are such that when cartridges are made up with it, they are sufficiently like the service cartridge to feed freer through the magazine, thus facilitating rapid fire practice.

Foot Note—Marksman powder is a new brand, similar to Schultz. Schultz is a shotgun powder, but when the manufacturers found that it was being used for rifles they modified it slightly so as to adapt it more particularly to the requirements. It will therefore be found that while the ballistic qualities of the two are similar, yet the Marksman will be a little more uniform in rifles and will keep better when loaded into dirty shells—although not so well as dense powders.

The bullets do not differ greatly from each other. No. 305259 is slightly larger than 308256, and will probably do better work in the Krag, which has a tendency to be above the standard size; while 308256 will do better in those guns that are closely chambered, and especially in the special barrels made by H. M. Pope and the Remington Arms Company.

Casting bullets is occasionally a stumbling block to the beginner, but is soon learned. Space forbids going into details, except to say that the mould should be hot and free from oil. Full instructions for preparing the alloy can be obtained from the Ideal Manufacturing Company, New Haven. Conn., who make the moulds for all of the bullets illustrated. A mould for making one bullet at a time costs about $1.50, while one for making eight at a time costs $10. After the bullets are cool they can be lubricated either by dipping them into melted lubricant, or cold lubricant can be forced into the grooves by means of the Ideal lubricating pump. The best lubricant I have found so far consists of two pounds of japan wax, one pound of mutton tallow and one pound of Vaseline melted together. Its consistency can be varied by putting in more or less Vaseline.

When using these reduced loads in the Krag the sights will have to be set about 350 to 400 yards above the elevation that would be required for the same distance with the service charge; the zero for the wind gauge will average one point left. This is not due so much to the difference in trajectory as to the absence of the violent jump of the full charge, while the correction for this jump is still on the gun.

If it is desired to reload the shells for long range shooting with the service charge, the jacketed bullets will have to be bought. But even here a great deal of money can be saved on the shells. For this purpose the shells should be resized, especially at the neck, after each firing. The best bullets to buy are the smooth Thomas bullets made by the U. M. C. Co., or the latest smooth bullets of the Peters Cartridge Company, known as the HH bullet. Both of these are capable of extreme accuracy, and it is hard to say which does the better shooting. If government made bullets must be used, the best of this make I have ever tested have been those supplied by Frankford Arsenal a couple of years ago in the cartridge known as "New Jersey Special No. 2." The jacketed bullets work best if kept entirely free of lubricant.

The powder charges for the service load should be 54 grains of Laflin & Rand W. A. powder. No other kind that is equal to it has so far made its appearance, as far as I know—and I have been keeping a sharp look out for such a powder. The W. A. is certainly a good powder, and I have never heard any complaint about it from any rifleman who was careful to load it intelligently. Its only fault is the difficulty of measuring it accurately. It is the weight that counts, not the bulk measure; and if exceptionally fine work at the longest ranges is desired, it is safer to weigh each charge.

Now as to expense. By these processes it is possible to get the cost of full service loaded cartridges, with jacketed bullets, to as low as $14.00 to $16.00 per thousand. Those cartridges that are loaded with cast bullets and recovered alloy can be made for $2.75 to $3.25 per thousand. Is not the ammunition question worth a little study, in view of this immense saving.

There are some persons who still insist that the reloading of metallic cartridges is a difficult piece of work, Winch the average soldier cannot hope to master. But I have a better opinion of the average soldier, and I some times think that if a little more attention were paid to developing the better points in his individuality rather than treating him as a mere drilling machine, results would be better all around. I know that the great majority of New England farmers’ boys who own a central fire rifle, soon learn to reload their own cartridges in a highly satisfactory manner; and I cannot believe that the average soldier is intellectually so much inferior to the farmer's boy that he cannot learn how to do it even when aided by the tuition of his officers.

W. G. Hudson, M. D., Capt. & Asst. Surgeon,

9th Regt. N. G. N. Y