Images are here, might not make sense, but they are included.

Specifcation forming part of Letters Patent No. 219,840, dated September 23, 1879; application filed July 28, 1879.

To all whom it may concern:

Be it known that I, WILLIAM W. WINCHESTER, of New Haven, in the county of New Haven and State of Connecticut, have invented certain Improvements in Methods of Manufacturing Bullets, of which the following is a specification.

This invention relates to an improved method of manufacturing what are known in the art as the “ Kean split or cruciform bullets.” These bullets have their forward ends provided with closed seams or slits, to facilitate the opening or spreading action upon encountering a bone or other hard resisting; object. These bullets are provided in the forward end with a central hole or cavity, a cap or plug to close the same, and with a series of closed seams or slits extending lengthwise and radiating from the central hole, whereby they are caused to expand and spread the more readily upon encounter in a bone or other hard resistance.

Hitherto the usual method pursued in the manufacture of these balls consisted in casting them in a complicated mold, with the recess and open slits in the front end, and subsequently finishing them and closing the seams by dies. This plan permitted the casting of but few bullets at a time, and rendered the production so slow and expensive that their general adoption was prevented.

My improved method consists in first casting the bullet with the recess, but without the slits, subsequently producing the slits by means of a saw or a knife, of suitable form, actuated by machinery, and finally compressing the bullet in a die to close the slits.

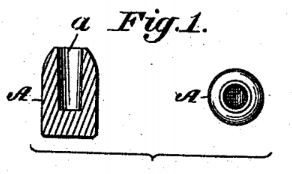

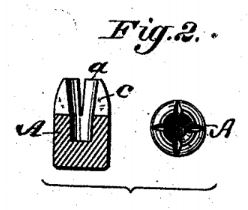

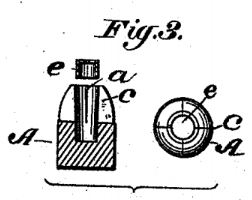

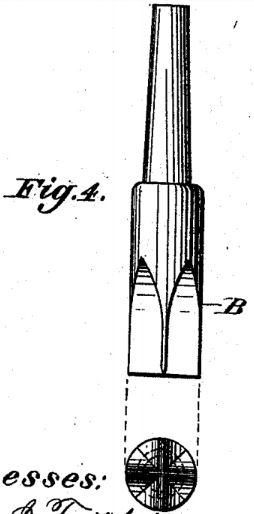

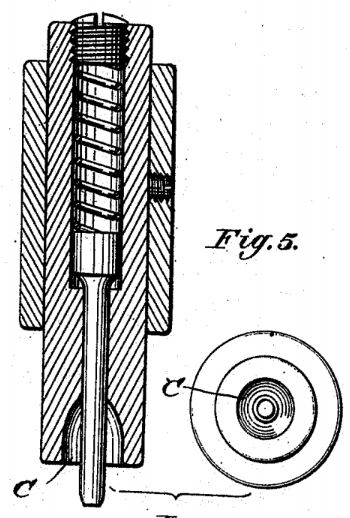

Figure 1 represents the bullet in its first form, the figure showing a longitudinal section and an end view. Fig. 2 illustrates the bullet as it appears after the cutting of the slits therein. Fig. 3 represents the finished bullet; Fig. 4, one form of the cutting or slitting tool; Fig. 5, one form of the die for compressing the bullet and closing the slits.

The bullet A is first made by casting or swaging in the form shown in Fig. 1, with a solid or unbroken front end having a central cavity or hole, a, therein. subjected to the action of a ‘knife or slitting punch, B, such as shown in Fig. 4, or any other suitable knife, saw, or other cutting tool, where by the longitudinal radial slits c are formed in the front end of the bullet, as shown in Fig. 2. After these slits are made the bullet is acted upon by a die, C, such as shown in Fig. 5, or any equivalent compressing device, where by it is compressed and reduced at the forward end, so as to close tightly the slits and give the bullet a smooth finished appearance. In other respects the exterior of the ball may be finished in any approved or desired manner.

The hole may be left open or closed by means of the inverted sheet-metal shell or cap e, as shown, or by other ordinary means.

My invention relates solely to the method of producing the body of the bullet.

What I claim as my invention is—

The herein-described method of making expansive bullets, consisting in first making the bullet with an unbroken tubular front end, subsequently cutting the slits therein, and finally compressing the front 'end to close the slits, substantially as set forth.

WILLIAM W. WINCHESTER.

Witnesses:

DANIEL H. VEADER,

WM. W. CONVERSE.