SR MicroSight on Williams FoolProof

Sight Experience

NOTE: This idle dallying was back in

2011, so things may have changed. Further editing and fact

checking... Initial mounting was to be on a 788, but I changed over

to a T/C Contender, as the 788 FP needed the stock to be cut away in

order to use the mounting holes.

Images to come, I have to insert them...

As always, send comments, questions, outright disbelief, whatever,

to me HERE

Optical

lens for rear peep (SR MicroSight - Phased Zone Plate)

(original post)

Stallings

Machine The Original SR MicroSight is based on a

development by a high power shooter (that just happens to work at a

federal research lab). David Crandall at Idaho National Laboratory.

MicroSight

Approved by CMP for Service Rifle Competition

Breakthrough

MicroSight Technology Improves Iron Sights

Amazing

New MicroSight Technology Moves into Production (Video of

MicroSight in use)

Fly in the ointment, they have two thread sizes (for service

rifle sights) of 1/4-32 or 1/4-28. Neither which will screw

into the Williams Sight Aperture (7/32-40).

Oh,

my. Length IS everything

OK, the old saying that length isn't everything is FALSE.

My dad was totally unable to get the Merit Target sight to work for

him on his 540XR, due to bad eyesight. Went downstairs, rummaged

about, pulled out my Micro-Sight, unscrewed the windage screw, took

off the stock Williams aperture housing, threaded on the 1/4x32

drilled housing, and came to a full stop. The normal shank for the

Micro-Sight is full threads right into the cylindrical optics

housing. The Micro-Sight in the original form will not fit no-way

no-how into a Williams aperture housing.

Careless measuring shows that the Williams apertures have an

unthreaded shank .100" long that spaces the disc @ .030 past the

edge of the windage arm. Rear end of aperture housing is @ .070"

from rear edge of windage arm. Stallings Machine will not make a

MicroSight housing with a .100" unthreaded shank extension.

Finally

found a combination - Micro-Sight mounted in Williams FP-T/C sight

Gods, what a nutroll, BUT it does fit. The

insurmountable problem was how to screw the 1/4-32 Micro-Sight boss

into an aperture housing and NOT have the exterior of the

Micro-Sight housing run into the back of the Williams windage arm.

This was not too difficult, BUT it took a bit of thinking, and

thinking without alcohol HURTS. Start to finish, @ 1 hour. Most of

that was setting up the fixture, finding the tap, and the target

knobs, and figuring out how to fully seat the knobs over the ball

bearings (having a 4" vice, or bigger, is good!)

Grab yourself a Williams 5/16 "Big Game"

aperture. I used my small hole gauge, and it comes out at .308-ish.

Get yourself a foot of K&S Engineering #3062, 5/16 OD aluminum

tubing (mics about .308-ish), with a wall thickness of .049". A 7/32

stub drill to clean up the ID. Brownells for a 1/4-32 tapered tap

(yeah, aluminum likes thread forming taps, but $$$...).

Chucked the aluminum tube up in a lathe

and hack sawed about .550 inch off. Chucked it onto the ER-32, (cut

edge up), co-ax'd the OD of the 5/16 tubing to less than .001 off

centre. drilled it out to 7/32, then tapped it to 1/4-32. NOTE: Aluminum prefers a light touch

when tapping with a normal, fluted tap, so I used a "sensitive" tap

wrench with the sliding arbor, not my normal spring loaded point.

Chucked the aluminum tube up in a lathe

and hack sawed about .550 inch off. Chucked it onto the ER-32, (cut

edge up), co-ax'd the OD of the 5/16 tubing to less than .001 off

centre. drilled it out to 7/32, then tapped it to 1/4-32. NOTE: Aluminum prefers a light touch

when tapping with a normal, fluted tap, so I used a "sensitive" tap

wrench with the sliding arbor, not my normal spring loaded point.

7/32-40 tap went right in with no binding. Used Tap-Magic for

aluminum, but any aluminum tapping fluid should do (WD-40). ER-32

chuck held tubing without slip..

Took a file, cleaned off the flash from the

hacksawing, and popped it out. Screwed the Micro-Sight into the

arbor, then pushed it into the aperture, using the workbench. Added

the short knobs (upgraded a non-TK version) and momentarily lost one

ball bearing and the teeny spring.

Big game Apertures

Foolproof

|

5D

|

The Foolproof Big Game aperture sorta cramps your

fingertips when using the TK elevation knob. The Big Game aperture

is wider than the stock aperture, so you loose some windage. If you

really need all of it, I suppose you could mill some clearance on

the underside of the aperture on each side. NOTE:

The Foolproof and the 5D use different attachments, FP is threaded

for Windage screw, 5D has slotted ears for screws.

The tubing snugly fits in the aperture so good it

is scary. Note that the aperture has a windage mark stamped at the 6

o'clock position, this seemed to be the reason the aluminum tubing

would only go in one way. Just install the aperture "backwards".

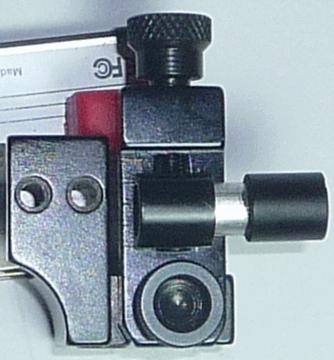

Side view.

|

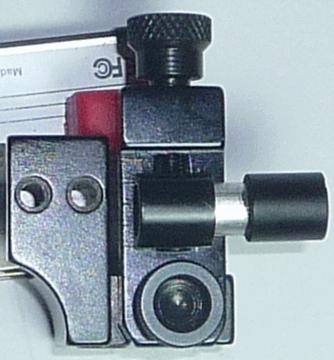

Top view

|

Aperture can be used as-is.

|

Concerned about Light Reflections?

Well, since it was in a ER-32 chuck, I could have

pulled the threaded arbor out, turned it end for end, and drilled

out the forward end to 1/4 inch. There are a number of flat black

finishes which could be used to coat the inside of the arbor,

reducing reflection (old timers, remember Em-New?)

For those with a lathe, yes you can turn a

stepped arbor, to go from 7/32-40 OD to 1/4-32 ID. BUT my way can be

done with a fair degree of precision and IMHO, is fairly idiot

proof. If one really wanted to go minimalist, you could probably use

.035 walls, and skip the 7/32 tap drill. Buy a cheap collet block

and a 5/16 collet.

One Possible Way to Mount

I used a Barrel band mount (.812 dia) for the front sight. I got a 3/16

Standard sight block from Steve Earle to

reduce the globe sight height.... IMHO, the barrel should be d/t for

a proper front sight base, but let's see if it works good.

Champion's

Choice has .812 Barrel Band, but has the sight block milled

on.

OK

Weber has a steel barrel band. Check for .812 availability.

Contender "Bull" barrels are .810 diameter, while the various

diameters for Barrel Band Sight Bases range from .750, .812, to .930

(other sizes exist as well!)

Chucked the aluminum tube up in a lathe

and hack sawed about .550 inch off. Chucked it onto the ER-32, (cut

edge up), co-ax'd the OD of the 5/16 tubing to less than .001 off

centre. drilled it out to 7/32, then tapped it to 1/4-32. NOTE: Aluminum prefers a light touch

when tapping with a normal, fluted tap, so I used a "sensitive" tap

wrench with the sliding arbor, not my normal spring loaded point.

Chucked the aluminum tube up in a lathe

and hack sawed about .550 inch off. Chucked it onto the ER-32, (cut

edge up), co-ax'd the OD of the 5/16 tubing to less than .001 off

centre. drilled it out to 7/32, then tapped it to 1/4-32. NOTE: Aluminum prefers a light touch

when tapping with a normal, fluted tap, so I used a "sensitive" tap

wrench with the sliding arbor, not my normal spring loaded point.