B-Square Super MagArbor Twin Post

Arbor Press - B-Square #: T0050

All Purpose Arbor Press, Twin Post Arbor Press, Super MagArbor Press

(Seems to be gone in 2006)

If someone has the Instructions or User Guide, please send me a

copy! HERE

B-Square Mag Twin Arbor Press easy and quick assembly

modification (Almost complete!)

Never letting up on "what if", I thought of using

my Mag Arbor Press on the range. Cool, but keeping it fully

assembled makes it blocky. When it was shipped to me, it was all

knocked down, and was relatively compact. Upon looking at the

design, and the actual thrusts, it became clear that the inner hex

nuts on the 1/2-13 stud were only there to keep the bottom and top

crosspieces apart. They do not have to deal with any force (other

than gravity) that is trying to compress the two cross pieces

together. Another function of the two inner hex nuts is to keep the

stud from turning while the outer hex nuts are tightened. The bottom

hex nut (under the bottom crosspiece) has to be able to withstand

the pull exerted during bullet seating.

So, with these mechanical facts in mind, I bought

two 7.5 inch [ed. looks like 6.5 inch is better] long pieces of 6061

tubing, 5/8 OD, .509 ID, wall of .058. These will replace the two

inner hex nuts on each stud. I bought two pieces of 1/2x7/8x1.125

[ed. use 1" stock, see below!] steel to drill n tap to 1/2-13, and

will loctite them to the bottom end of each stud. This will just fit

in the recess in the bottom cross piece (1.2 ish wide) , preventing

any turning while tightening the upper fastener. I just bought two

1/2-13 threaded nuts to replace the top hex nut. The whole

shebanga-bang should quickly assemble or take-down, and store in a

relatively small space.

The extra bits could be easily fabricated from

stock, but I let the good folks at Speedy Metals do the cutting (cut

square, cut clean, and fast shipping). McMaster had the knurled

nuts, with no minimum order. You could buy 1/2-13x12 T Bolts, but

they are about $5 each.

Knocking it down will result in two t-bolts, each

with it's own aluminum tubing spacer, a washer, and a knurled nut on

it. The upper and lower crosspieces. Assembly should be quick,

unscrew the knurled nuts, slide the spacer and washer off each

t-bolt, stick the end of each t-bolt through the bottom crosspiece,

add the spacers, put the top crosspiece on the bolts, add the

washers, then fasten things down with the knurled nuts. QED.

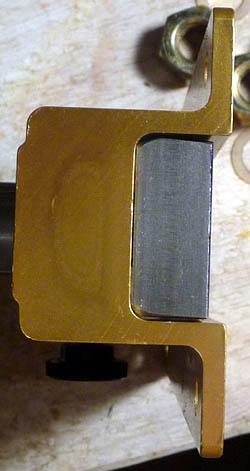

Stock metal for T Bolt

heads. They were a bit over, with the rounded angle of the B-Square

base interfering. I recommend having the stock cut to 1", for less

machining. I will be putting a 45 degree chamfer on the upper ends

so they fit the underside of the base. Note that the farther T Bolt

head is not flush with the base (nor is the other head flush!).

Cranking down on the top nut would apply pressure on the ends of the

T Bolt head, not what I want...

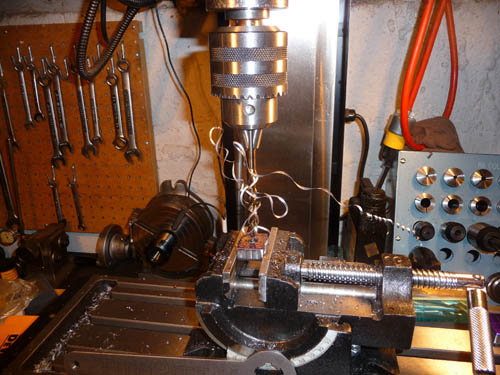

I found grinding the extra off of the T Bolt

stock to be tedious. Instead, I mounted a vise, used a 90 degree

square to align the stock in the jaws, and milled one end down.

Measured the machined block, came up with 1.17, set up the next

piece, took off .030, and the two pieces match for length.

Good ol' 1018 CRS....

Side view, showing the radiused corners of the

B-Square Arbor press.

Finished T-Bolt heads, sans loctite.

Almost complete quick-mod.

Well, had to clean up the chuck on the lathe... Using emery cloth

leaves an abrasive coating on the ways and the chuck jaws...

Anyways, dug up my Brown and Sharpe 12" aircraft scale (uses more

precise markings, down to 100ths), slapped on some Dykem, marked off

6 1/2 inches on the tubes, then parted. A few turns with the Noga to

debur, a little twirling on the belt sander, and put it together.

As expected, facing the tube end and parting to the same length

removed most, if not all, of the canting. Picked up two 1/2 inch

washers to protect the top crosspiece from the friction from the hex

nut (knurled nut). The original B-Square press used plastic

"spacers", which do not stand up well if crushed under the top nut

down into the hole around the stud. Once the plastic washer is

forced into the hole around the stud, it requires a mallet to force

the stud down far enough to free it...

Might have to part off another 1/2 inch, we'll see after some

use....